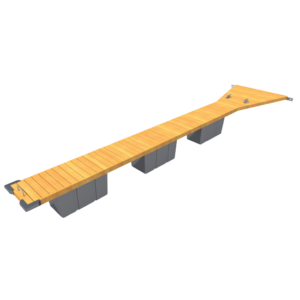

Marinetek FN Mooring Fingers have been designed according to the Australian Standards, which are most used in the marina industry. The frame is made of a hot dip galvanised and a very strong welded steel structure. The Fingers have composite or treated soft wood deck and side fenders and plastic fenders at the top edges. The connection to pontoon is with semi-flexible rubber bolt joints. The Fingers are very stable and long lasting.

Voor elke situatie een passend ontwerp gemaakt en geleverd

Innovatief en gespecialiseerd in verankeringstechnieken

Veiligheid en kwaliteit staan bij JLD voorop. Wij zijn VCA**- en ISO 9001- gecertificeerd!

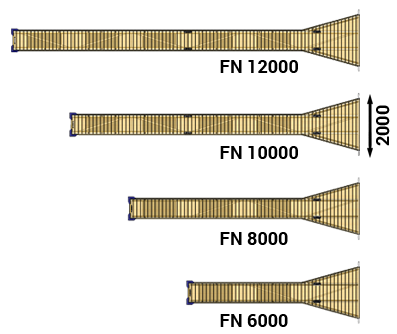

| STANDARD MODELS | FA6000 | FA8000 | FA10000 | FA12000 |

| Length (m) | 6,0 | 8,0 | 10,0 | 12,0 |

| Width (m) | 0,7 | 0,7 | 0,7 | 0,7 |

| Total capacity (kg) | 520 | 780 | 1040 | 1300 |

| Joint bolt | 2xM20 | 2xM20 | 2xM20 | 2xM20 |

Fingers of special lengths and widths are also available.

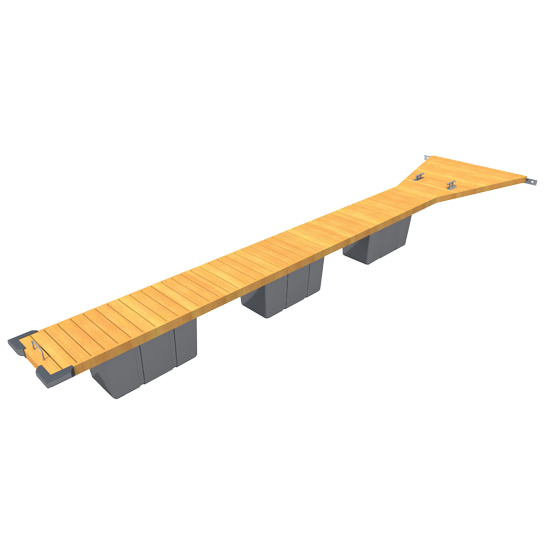

Standard fingers suit best for pontoons with freeboard up to 0,56 m. For higher freeboard, a higher float is available upon request.

Marinetek operates a policy of continous development and reserves the right to change specifications without notice.

Standard fingers suit best for pontoons with freeboard up to 0,56 m. For higher freeboard, a higher float is available upon request.

Marinetek operates a policy of continous development and reserves the right to change specifications without notice.

- Frame: Hot rolled steel, galvanised to EN ISO 1461

- Float: Rotation moulded polyethylene float M31L (260 kg)

- Decking: Treated pine (standard) or wood plastic composite

- Fender: Treated pine (standard), PVC- plastic or wood plastic composite