Proef met JLD-dijkstabilisator: Dijk versterken met diagonaal geplaatste elementen.

Proef met JLD-dijkstabilisator: Dijk versterken met diagonaal geplaatste elementen.

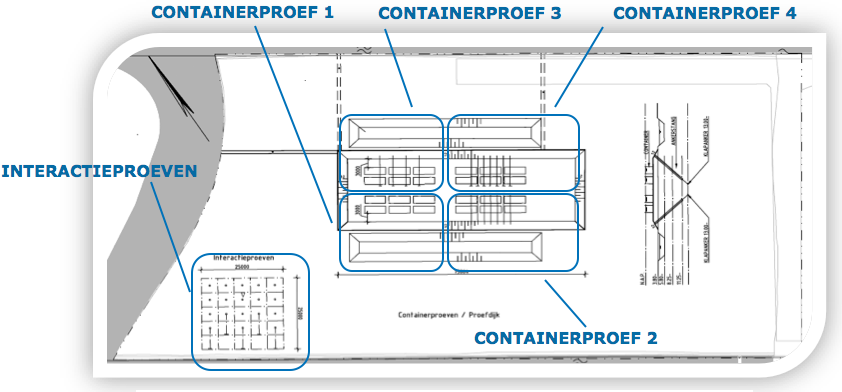

Het projectteam is druk bezig met het uitvoeren van de beproevingen van de dijkstabilisator. De eerste fase beproevingen zijn de zogenaamde interactieproeven welke op dit moment in het proefveld in Purmerend worden uitgevoerd. De beproeving bestaat uit verschillende trekproeven waarbij de dijkstabilisator in verschillende configuraties wordt getest. Naast trekken aan enkel LDE of klapanker wordt de dijkstabilisator in zijn totale samenstelling (LDE met klapanker) getest.

De dijkstabilisatoren zijn eerst in het proefveld aangebracht met behulp van een speciaal door JLD contracting ontwikkelde machine.

Vervolgens worden alle aangebrachte dijkstabilisatoren stuk voor stuk getest. Hierbij wordt aan de dijkstabilisator getrokken met behulp van een vijzel.

Op dit moment zijn bijna alle test van deze fase afgerond, de resultaten zijn bevredigend.

Ondertussen zijn de voorbereidingen voor uitvoering van de volgende fase beproevingen, de containerproeven, opgestart.

Artikel uit het Noord-Hollands dagblad 07-02-2025

Honderdzestig technici naar Purmerend.

JLD Contracting uit Edam start proeven om dijken te versterken met revolutionaire dijkstabilisator.

In 2013 is JLD Contracting BV een samenwerking aangegaan met Antea Group en Wiertsema & Partners. Met de steun van deze partners is JLD Contracting BV samen met Waterschap Rivierenland een uniek partnership aangegaan om de JLD-dijkstabilisator binnen het programma van de HWBP van een concept tot een geaccepteerd systeem te brengen. Deze innovatieve dijkverbeteringstechniek, die met name tot doel heeft de binnenwaartse stabiliteit te verbeteren, is een uitvoering en naar gepatenteerd idee van Dhr. Jos F. Karsten, directeur/eigenaar van JLD Contracting BV, dat is gevestigd in Edam. Gezamenlijk met de partners is er met Deltares die namens de opdrachtgever Waterschap Rivierenland de ontwikkeling begeleid een proefopzet gemaakt. Na zeer uitgebreid grondonderzoek en een reken exercitie en vele overleggen zijn de beproevingen op een door de gemeente Purmerend ter beschikking gestelde locatie aangevangen. Een van de basis gedachten zijn dat wat al onderzocht en bruikbaar is niet nogmaals onderzocht dient te worden. Deze data die veelal beschikbaar voor de markt is zal optimaal worden benut binnen deze ontwikkeling. Onderstaand geven we op hoofdlijnen een doorkijk in de werking van het systeem en de wijze waarop de beproeving verloopt.

Stand van zaken ontwikkeling JLD-dijkstabilisator

De voorbereidingsfase is gereed en het projectteam is begonnen met de eerste beproevingen. Alle betrokken partijen zijn in samenwerking met Deltares vol commitment aan het werk voor het project. Dit heeft geleid tot de proevenopzet waaruit we alle benodigde informatie ten behoeve van de kennisleemtes kunnen halen.

In het veld is de toplaag ter plaatse van de proefdijk afgegraven en hierop is het dijklichaam aangebracht tot ca. 1,40 m hoog. Tevens zijn de verschillende monitoringsystemen aangebracht, waaronder waterspanningsmeters en zakbakens. De ondergrond en de klei voor het dijklichaam worden onderzocht middels samendrukkingsproeven, single stage tri-axiaal proeven en DSS-proeven. Van het dijkmateriaal worden tevens Atterbergse grenzen bepaald en het volumegewicht/watergehalte bepaald.

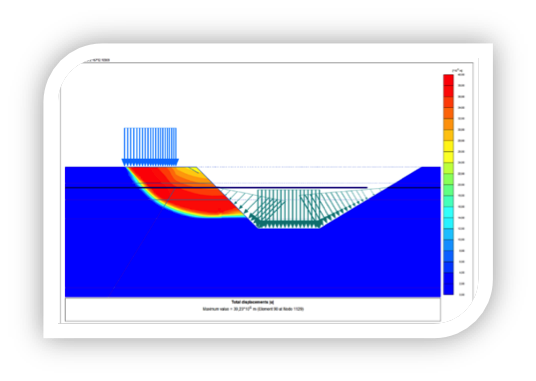

De proeven worden gemodelleerd in Plaxis 2D/3D om te controleren in welke mate de stabilisatoren in theorie bijdragen aan de macrostabiliteit van het dijklichaam en hoe de proef het beste uitgevoerd kan worden zodat de gewenste glijcirkel ontstaat. Rechts een illustratie van de werkzaamheden aan de stabiliteitsanalyse voor de containerproef/proefdijk .

Figuur 1: Stabiliteitsanalyse containerproef

Planning

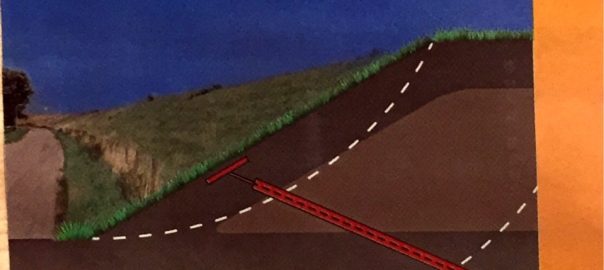

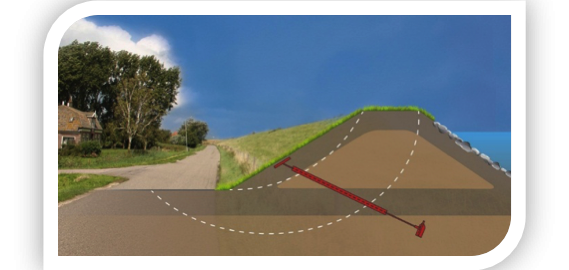

Werking systeem JLD-dijkstabilisator

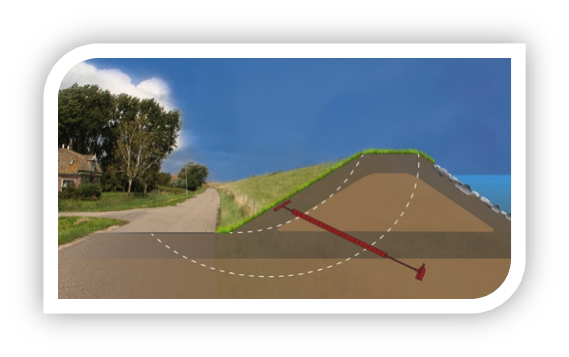

Doel: Verbeteren binnenwaartse stabiliteit

De JLD-dijkstabilisator is opgebouwd uit vier onderdelen:

| Klapanker | Brengt trekkracht over naar de ondergrond |

| LDE (vin) | Element brengen de dwarskracht over naar de bodem |

| Trekstang | Brengt dwarskracht via LDE naar JLD-klapanker/LDE |

| LDP (kopplaat) | Koppelt oppervlak aan JLD-dijkstabilisator |

Figuur 2: Werking systeem JLD-dijkstabilisator

Beproeving systeem JLD-dijkstabilisator

De stap die van belang is na het uitwerken van de theoretische onderbouwing is een

praktijkproef. De proeven hebben als doel het controleren of de JLD-dijkstabilisator werkt zoals is aangenomen in de theoretische onderbouwing en zoals blijkt uit de verschillende modelleringen. De proeven zijn onderverdeeld in twee onderdelen; de interactieproeven en de containerproeven.

Hoofddoel interactieproeven:

Hoofddoel containerproeven:

Figuur 3: Proevenopzet

Figuur 3: Proevenopzet

Ontwikkelingskosten

De gehele ontwikkeling wordt mogelijk gemaakt door de nieuwe regeling die het HWBP biedt.

Binnen de nieuwe regeling worden innovatieve projecten voor de volle 100% (ipv 90%) gefinancierd en de risico’s die te maken hebben met het eventueel niet slagen van de innovatie worden gedragen door het programma. Uiteraard heeft JLD Contracting binnen de risicokaart ook zijn verantwoordingen diezich met name richten op de uitvoering en de materialen. De energie, het commitment en de snelheid waarmee het project wordt uitgevoerd bewijst dat de nieuwe opzet van het HWBP vele kansen biedt die ook voor MKB bedrijven de mogelijkheid kan bieden om mooie ideeën tot uitvoering te kunnen brengen.

In de Scan die het HWBP jaarlijks doet wordt de JLD Dijkstabilisator ook gezien als zeer kansrijk.

JLD Contracting bv en zijn partners zijn zeer positief over het welslagen van deze ontwikkeling. De eerste resultaten die uit de beproevingen komen zijn zeer bevredigend.

Afgelopen 20 t/m 23 januari was JLD Contracting aanwezig op de Infratech 2015 beurs in Ahoy Rotterdam.

Deze editie van de InfraTech beurs stond JLD er met een prachtige stand om naast het succesvolle concept “JLD klapanker” de nieuwste ontwikkelingen genaamd de Dijkstabilisator en de VPPS (pijpleiding druksysteem) te promoten.

De JLD-Dijkstabilisator is een project waar JLD Contracting momenteel samen met partners Antea group, Wiertsema & Partners en Waterschap Rivierenland aan werkt om devar link = document.getElementById(‘link2736’);link.onclick = function(){document.location = link.getAttribute(‘href’);} dijken te versterken. De uitvoering vindt plaats binnen het HWBP programma,

“POV Macrostabiliteit”. De VPPS is een project waar JLD Contracting samen met partner Gasunie aan werkt om snel goedkoop en effectief o.a. transportleidingen in de grond aan te leggen of dieper te drukken in geval van dekking manco’s. .

De stand werd druk bezocht en er waren veel geïnteresseerden.

Snel meer nieuws over de Klapankers, Dijkstabilisator en VPPS!

Bekijk hiervar link = document.getElementById(‘link2736’);link.onclick = function(){document.location = link.getAttribute(‘href’);} onder de video’s die op de beurs zijn vertoond: